Concept explainers

Sequence the jobs shown below by using a Gantt chart. Assume that the move time between machines is on” hour. Sequence” the jobs in priority order 1, 2, 3, 4.

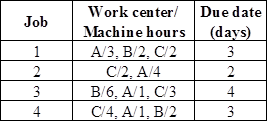

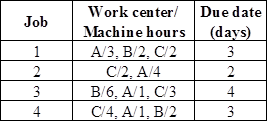

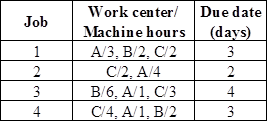

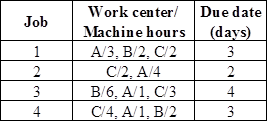

| JobWork | Center/Machine Hours | Due Date (days) |

| 1 | A/3, B/2, C/2 | 3 |

| 2 | C/2, A/4 | 2 |

| 3 | B/6, A/1, C/3 | 4 |

| 4 | C/4, A/1, B/2 | 3 |

- a. What is the make span?

- b. How much machine idle time is there?

- c. When is each job delivered compared with its due date?

- d. How much idle time (waiting time) is there for each job?

- e. Devise a better job sequence for processing.

a)

To determine: The makespan.

Introduction:

Gantt chart is the tool used to allocate the resources and schedule the tasks of projects.

Answer to Problem 3P

The makespan is 18 hours.

Explanation of Solution

Given information:

Moving time between the machines is one hour and sequence is given as 1, 2, 3, and 4. In addition to this, the information is given below:

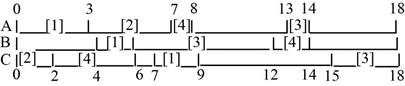

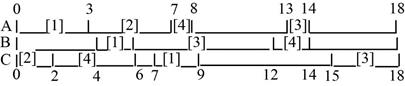

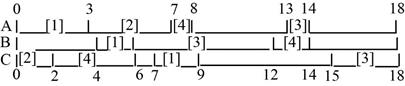

Construct the Gantt chart:

Hence, the total makespan is 18 hours (refer the Gantt chart).

b)

To determine: The machine idle time.

Introduction:

Gantt chart is the tool used to allocate the resources and schedule the tasks of projects.

Answer to Problem 3P

The machine idle time is 24 hours.

Explanation of Solution

Given information:

Moving time between the machines is one hour and sequence is given as 1, 2, 3, and 4. In addition to this, the information is given below:

Construct Gantt chart:

Determine the idle time for Machine A:

It can be determined that subtracting the sum of machine hours from the total makespan.

Determine the idle time for Machine B:

It can be determined that subtracting the sum of machine hours from the total makespan.

Determine the idle time for Machine C:

It can be determined that the subtracting the sum of machine hours from the total makespan.

Determine the machine idle time:

It can be calculated by adding the idle time of Machine A, Machine B, and Machine C.

Hence, the total machine idle time is 24 hours.

c)

To determine: The delivery time of each job compared to due dates.

Introduction:

Gantt chart is the tool used to allocate the resources and schedule the tasks of projects.

Answer to Problem 3P

The delivery time does not exist due date.

Explanation of Solution

Given information:

Moving time between the machines is one hour and sequence is given as 1, 2, 3, and 4. In addition to this, the information is given below:

Construct Gantt chart:

Determine the delivery time:

Due date is given in days. It must be converted to hours by considering working hours per day is 8 hours.

| Job | Due date (hours) | Delivery time (hours) |

| 1 | 24 | 9 |

| 2 | 16 | 7 |

| 3 | 32 | 18 |

| 4 | 24 | 14 |

Delivery time is taken from the Gantt chart. Example: Job 1 is on its 9th hour at last. After that there is no Job 1.

d)

To determine: The idle time of the jobs.

Introduction:

Gantt chart is the tool used to allocate the resources and schedule the tasks of projects.

Answer to Problem 3P

The job idle time is 11 hours.

Explanation of Solution

Given information:

Moving time between the machines is one hour and sequence is given as 1, 2, 3, and 4. In addition to this, the information is given below:

Construct Gantt chart:

Determine the idle time of the jobs

There is no idle time for Job 1 and Job 2. However, Job 3 has the idle time of 6 hours in Machine C from 9th hour to 15th hour (Refer Gantt chart). Job 4 has the idle time of 5 hours in Machine A from 8th hour to 13th hour (Refer Gantt chart).

Hence, the total idle time is 11 hours.

e)

To determine: The better sequence for processing.

Introduction:

Gantt chart is the tool used to allocate the resources and schedule the tasks of projects.

Answer to Problem 3P

The makespan is 14 hours and the better sequence is 3, 2, 4, and 1.

Explanation of Solution

Given information:

Moving time between the machines is one hour and sequence is given as 1, 2, 3, and 4. In addition to this, the information is given below:

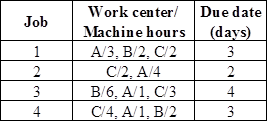

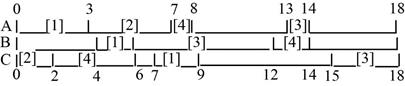

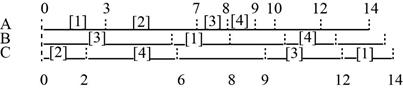

Construct the Gantt chart:

Hence, the total makespan is 14 hours (refer the Gantt chart).

Determine the idle time for Machine A:

It can be determined that subtracting the sum of machine hours from the total makespan.

Determine the idle time for Machine B:

It can be determined that subtracting the sum of machine hours from the total makespan.

Determine the idle time for Machine C:

It can be determined that subtracting the sum of machine hours from the total makespan.

Determine the machine idle time:

It can be calculated by adding the idle time of Machine A, Machine B, and Machine C.

Hence, the total machine idle time is 12 hours.

Determine the delivery time:

Due date is given in days. It must be converted to hours by considering the working hours per day as 8 hours.

| Job | Due date (hours) | Delivery time (hours) |

| 1 | 24 | 14 |

| 2 | 16 | 7 |

| 3 | 32 | 12 |

| 4 | 24 | 12 |

Delivery time is taken from the Gantt chart. Example: Job 2 is on its 7th hour at last. After that there is no Job 2.

Hence, the sequence 3, 2, 4, and 1 is better in makespan and idle time.

Want to see more full solutions like this?

Chapter 12 Solutions

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

- The times required to complete each of eight jobs in a two-machine flow shop are shown in the table that follows. Each job must follow the same sequence, beginning with machine A and moving to machine B. TIME (hours) Job Machine A Machine B a 16 5 b 3 13 c 8 7 d 9 6 e 2 14 f 14 4 g 18 14 h 20 11 Find machine B’s idle time For the sequence determined in part a, how much would machine B's idle time be reduced by splitting the last two jobs in half?arrow_forwardThe following table shows orders to be processed at a machine shop as of 8:00 a.m. Monday. The jobs have different operations they must go through. Processing times are in days. Jobs are listed in order of arrival. Job Processing Time (Days) Due Date (Days) Remaining Number of Operations A 8 20 2 B 10 18 4 C 5 25 5 D 11 17 3 E 9 35 4 Click here for the Excel Data File a. Determine the processing sequence at the first work center using each of these rules: (1) First come, first served, (2) Slack per operation. (Hint: In case of a tie choose the jobs in alphabetical order.) b. Compute the effectiveness of each rule using each of these measures: (1) average completion time, (2) average number of jobs at the work center. (Round your answers to 2 decimal places.)arrow_forwardProcessing time for eight projects, displayed in the sequence they arrived. Project P1 P2 P3 P4 P5 P6 P7 P8 Processing time (hours) 3 1 1 2 9 6 1 1.50 2. Given the projects displayed in table above, if FCFS is used to sequence the jobs, what is the average flow rate of the projects? Note: Round your answer to 2 decimal places. 3. Given the projects displayed in table above, if FCFS is used to sequence the jobs, what is the average flow time of the projects? Note: Round your answer to 1 decimal place. 4. Given the projects displayed in table above, if FCFS is used to sequence the jobs, what is the average inventory of the projects? Note: Use your rounded answers from Parts 2 and 3. Round your answer to 1 decimal place. 5. Given the projects displayed in table above, if SPT is used to sequence the jobs, what is the average flow rate of the projects? Note: Round your answer to 2 decimal places. 6. Given the projects displayed in table above, if SPT is used to sequence…arrow_forward

- Five welding jobs are waiting to be processed. Their processing times and due dates are given below. Using the critical ratio dispatching rule, in which order should the jobs be processed? All dates are specified as days from today. A B, D, A, E, C B C, E, A, D, B C E, B, A, D, C D C, D, A, B, E Job A B Processing Time (days) 4 2 Job due date (days) 7 4 C 8 11 D 3 5 E 5 11arrow_forwardThe following table contains information regarding jobs that are to be scheduled through one machine. Assume jobs are listed in order of arrival (i.e., A, then B, then C, etc.). PROCESSING JOB TIME (DAYS) ABCDEFG Α 3 16 с 11 622845 DUE DATE 24 21 19 18 17 6 8 (Round your answers to Part e to 1 decimal place. Enter your answers to Parts a-d as whole numbers.) a. What is the first-come, first-served (FCFS) schedule? Job Flow Timearrow_forwardIf the cycle time is 65.4 seconds and A is assigned as the first task in Workstation #1, what is the idle time after assigning task A? Task Task Time (seconds) Tasks That Must Precede Other Tasks Number of Following Tasks A 28 - 7 B 13 - 8 C 35 B 7 D 11 A 6 E 20 C 6 F 6 D, E 5 G 23 F 3 H 25 F 2 I 37 G 1 J 11 G, H 1 K 27 I, J 0 Total 236 a. 26.9 minutes b. 37.4 seconds c. 28.5 seconds d. 31.6 seconds e. 57.6 secondsarrow_forward

- Five jobs are ready for processing at time zero through a workstation. The details of the processing time and the due date of completion is provided in the following table. According to EDD, what is the optimal sequence? Job Processing Time (days) Due Date A 8 12 B 4 9 IC 3 6 7 E 5 20 a) E-A-B-D-C b) C-B-E-D-A c) A-B-C-D-E d) C-D-B-A-Earrow_forwardThe following table contains information concerning four jobs that are awaiting processing at awork center.JobJob Time(days)Due Date(days)A 14 20B 10 16C 7 15D 6 17a. Sequence the jobs using (1) FCFS, (2) SPT, (3) EDD, and (4) CR. Assume the list is by orderof arrival.b. For each of the methods in part a, determine (1) the average job flow time, (2) the average tardiness, and (3) the average number of jobs at the work center.c. Is one method superior to the others? Explain.arrow_forwardGiven the projects displayed in Table 18.21, if SPT is used to sequence the jobs, what isthe average inventory of the projects (in projects)?arrow_forward

- A foreman has determined the expected processing times at a machine for a set of jobs and now wants to sequence them. Given the following information, do the following: Job Time Due Date Job (days) (days) a 4.5 10 6.0 17 5.2 12 d. 1.6 27 e 2.8 18 f 3.3 19 a-1. Determine the processing sequence using (1) MST, (2) SPT, (3) EDD, and (4) CR. Rule Sequence a-с-b-е-f-d MST d-e-f-a-c-b SPT a-c-b-e-f-d EDD a-c-b-f-e-d O CR a-2. For each sequence, calculate the average days late, the average flow time, and the average WIP. (Do not round intermediate calculations. Round the final answers to 2 decimal places.) Rule Average lateness Average flow time Average WIP day (s) day (5) MST & EDD day(s) jobs day (s) jobs SPT day (s) day (s) jobs CR b. Which rule is best? SPT O has the lowest average flow time & average WIP, but EDD & MST have the lowest average days late.arrow_forwardEight jobs have arrived in the following order: Job Processing Time Due Date 1 25 11 12 9 2 3 4 5 6 7 8 9 5 11 st 4 10 7 16 6 18 16 Find and compare the performance measures for the following sequencing rules using the Excel Sequencing template. Round your answers to two decimal places. A. Process in the order they have arrived 24 42 Average Flow Time Lateness Tardiness Average B. Shortest processing time The SPT sequence is 4, 2, 8, 6, 1, 5, 3, 7 Flow Time Lateness Tardiness Average Earliest due date The EDD sequence is 4, 2, 3, 8, 5, 6, 1, 7 Flow Time Lateness Tardinessarrow_forwardThe following six jobs are to be scheduled on a single machine: Job 1 2 3 Processing time 70 160 220 (min.) a. Suppose the jobs are processed in FCFS numerical order. Compute the makespan, flow time for each job, and overall average flow time. Round your answers to the nearest whole number. Job Flow Time (min) 1 2 3 st 4 5 6 4 5 6 90 130 110 minutes Makespan: Average flow time: minutes b. In what order would the jobs be processed using the SPT rule? The SPT sequence is -Select- -Select- -Select-- -Select- ✓ -Select- -Select- Compute the average flow time after each job is completed. Round your answer to the nearest whole number. Average flow time: minutesarrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.