Concept explainers

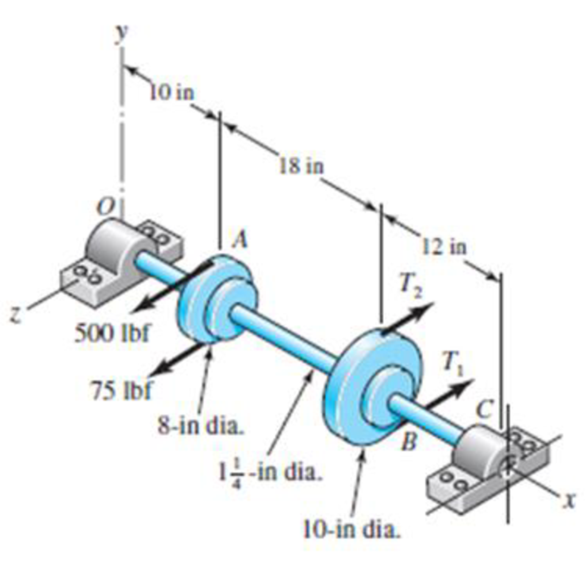

A countershaft carrying two V-belt pulleys is shown in the figure. Pulley A receives power from a motor through a belt with the belt tensions shown. The power is transmitted through the shaft and delivered to the belt on pulley B. Assume the belt tension on the loose side at B is 15 percent of the tension on the tight side.

11-14* to 11-17* For the problem specified in the table, build upon the results of the original problem to obtain a Basic Load Rating for a ball bearing at C with a 95 percent reliability, assuming distribution data from manufacturer 2 in Table 11-6. The shaft rotates at 1200 rev/min, and the desired bearing life is 15 kh. Use an application factor of 1.2.

| Problem Number | Original Problem, Page Number |

| 11-14* | 3-68, 151 |

| 11-15* | 3-69, 151 |

| 11-16* | 3-70, 151 |

| 11-17* | 3-71, 151 |

Want to see the full answer?

Check out a sample textbook solution

Chapter 11 Solutions

Shigley's Mechanical Engineering Design (McGraw-Hill Series in Mechanical Engineering)

- The figure 1 shows a pulley assembly that consists of a shaft supported by two bearings and driven by a motor on the righthand side (not shown in the figure). The shaft diameter is 100mm. The pulley consists of two disks, each disk is 15 mm thick and has an outer diameter of 620mm, that are connected by means of a cylindrical shell. The length of the shell is 500mm, the outer diameter of the shell is 600mm, and the thickness of the shell is 15mm. The pulley drives a belt that places a uniformly distributed load on the shell (of 100000N) as shown in the diagram. The belt lifts a load that applies a torque of 6000Nm to the pulley. The shell and the plates are connected. A 6mm fillet should be applied to all the 90 degree corners between the shaft and the plates and between the shell and the plates. Apply the boundary conditions and the forces and torques to the system and determine the following: Calculate the highest Principal stresses in the system ?arrow_forwardThe figure 1 shows a pulley assembly that consists of a shaft supported by two bearings and driven by a motor on the righthand side (not shown in the figure). The shaft diameter is 100mm. The pulley consists of two disks, each disk is 15 mm thick and has an outer diameter of 620mm, that are connected by means of a cylindrical shell. The length of the shell is 500mm, the outer diameter of the shell is 600mm, and the thickness of the shell is 15mm. The pulley drives a belt that places a uniformly distributed load on the shell (of 100000N) as shown in the diagram. The belt lifts a load that applies a torque of 6000Nm to the pulley. The shell and the plates are connected. A 6mm fillet should be applied to all the 90 degree corners between the shaft and the plates and between the shell and the plates. The highest stress in the systemarrow_forwardA countershaft carrying two V-belt pulleys is shown in the figure. Pulley A receives power from a motor through a belt with the belt tensions shown. The power is transmitted through the shaft and delivered to the belt on pulley B. Assume the belt tension on the loose side at B is 15 percent of the tension on the tight side.arrow_forward

- For nos. 21-23, satisfy the conditions of the given problem below: As an airplane's brakes are applied, the nose wheel exerts two forces on the end of the landing gear as shown in the figure 1. Determine: 21. the force in the strut AB. * 1 point 30° 450 lb. 1350 lb O A. 215.3 lb B. 224.4 lb C. 233. 2 lb D. 234.3 lb 1 ft 2 ftarrow_forwardFor nos. 21-23, satisfy the conditions of the given problem below: As an airplane's brakes are applied, the nose wheel exerts two forces on the end of the landing gear as shown in the figure 1. Determine: 21. the force in the strut AB. * 1 ft -20% 2 ft 1350 lb 30% 450 lb. A. 215.3 lb B.224.4 lb C. 233, 2 lb D. 234.3 lb Option 5 22. the horizontal component at the pin C. * A. 628.6 lb B. 627.8 lb C. 634.4 lb D. 652.3 lb 23. the vertical component at the pin C. A. 1468 lb B. 1485 lb C. 1500 lb D. 1526 lbarrow_forwardA gear-reduction unit uses the countershaft depicted in the figure. Find the two bearing reactions.The bearings are to be angular-contact ball bearings, having a desired life of 60 kh when used at 330 rev/min. Use 1.2 for the application factor and a reliability goal for the bearing pair of 0.92arrow_forward

- The degree of freedom of the geared five bar mechanism as shown in figure isarrow_forwardDetermine the degree of freedom (F) of the mechanism using the general degree of freedom equation. Write down the number of limbs on the figure. Also, specify the number of joints and the degree of freedom of each marshall. b) Determine the number of common (j1) and high (j2) pairs and show them on the figure. (c) Determine the degree of freedom using Kutzbach's criterion. Does this criterion provide the correct answer for this mechanism? Briefly explain why or why not.arrow_forwardIn the figure below, a motor with power 150kw and speed of 2500 rpm is connected to shaft 1(by coupling) in a clockwise direction. Shaft 2 is connected to shaft 1 by gears 1 and 2. If 30% of the power is consumed by the gear3 and 9% by the pulley and 61% by the sprocket, draw torque diagrams for both shafts. If the pressure angle of the gears is 20 degrees to the x-axis, Calculate the reaction forces of the bearings and draw the bending moment diagrams for both shafts according to the information below: Lengths: AB=90mm/BC=DGH=50mm/CD=HI=60mm/DE=IJ=80mm Diameters: dG1=dG2=47mm/ dG3=20mm/ d(pulley)=35mm/d(sprocket)=40mm Gears Gear2 Tew) shaftz Bearing Shaft Gear1 SProcketarrow_forward

- The pedal system shown in the figure is exerted by both an up and down mechanism. These forces are Fmax=350*SN/10 N, Fmin=-150*SN/10 N. It is desired that h/b = 5 seen in the figure. This piece is AISI 1040 and has a maximum tensile stress of 670Mpa and a yield stress of 540Mpa. Known weakening factors are known as kb=ky=kd=0.8. The notch factor for all stresses is assumed to be Kç=1.5. It is desired to last up to its minimum indefinite life at the cross-section measurement point (bxh) shown in the figure. According to Goodman theory, what should be the minimum size (b and h value) of this section in order to meet this condition. SN=89arrow_forwardRequired information A countershaft carrying two V-belt pulleys is shown in the figure. Pulley A receives power from a motor through a belt with the belt tensions shown. The power is transmitted through the shaft and delivered to the belt on pulley B. Assume the belt tension on the loose side at B is 15 percent of the tension on the tight side. Given: B(dB) = 205 mm, T(A) = 1880 N, and T(A2) = 282 N. NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. B(dB) 230 mm T₂ G 30-mm dia. 100 400-mm dia. T(A₁) 280 mm The bending stress at the point of maximum bending moment is At the point of maximum bending moment, determine the bending stress and the torsional shear stress. The torsional shear stress at the point of maximum bending moment is 300 mm MPa. T(A₂) MPa.arrow_forwardThe machine is designed to be powered by a 100 HP electric motor at a speed of 1500 rpm, with standard D-120 V-belts. The pitch diameter of the smaller sheave is 101.6 mm and the bigger sheave is 406.4 mm. Service factor is 1.25. Use length of D-120 V-belt equal to 123.3 inches. Determine the center distance between sheaves in mm; the arc of contact in deg; and the design in HP.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY