Concept explainers

Suppose that you wanted to machine cast iron with BHN of 275. The process to be used is face milling and an HSS cutter is going to be used. What feed and speed values would you select?

Feed and speed value for the face milling.

Explanation of Solution

Given:

Part is cast iron.

Hardness number is 275.

Face milling with HSS cutter is used.

Cutting speed and feed per tooth for the milling operation is selected by the tool operator or engineer. These cutting velocity and feed depends on tool material, specific process and work material.

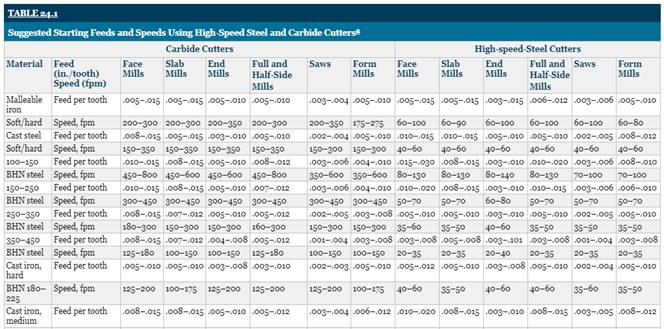

Following tables shows the cutting speed and fee for different material, cutter and milling process:

From above table,

Feed can be selected for cast iron is 0.005 − 0.012.

Cutting velocity can be selected for the cast iron as 20-35 fpm.

Want to see more full solutions like this?

Chapter 24 Solutions

Degarmo's Materials And Processes In Manufacturing

Additional Engineering Textbook Solutions

Thinking Like an Engineer: An Active Learning Approach (4th Edition)

Fundamentals Of Thermodynamics

Fundamentals of Heat and Mass Transfer

Applied Statics and Strength of Materials (6th Edition)

Manufacturing Engineering & Technology

Introduction To Finite Element Analysis And Design

- Calculate spindle RPM and machining time for cutting a 1.5" diameter 4" long at 225 SFPM using a feed rate of 0.004".arrow_forwardFind the machining time required to turn a mild steel rod from 65mm to 58 mm over a length of 100 mm by using a carbide insert. If the approach length and over run length is taken as 5 mm, Cutting speed as 20 m/min and feed is =0.2 mm/rev, and the depth of cut is 0.5mmarrow_forwardA shaft groove with a length of 250 mm and a depth of 12 mm is cut by a 20 mm diameter slot cutter. What is the processing time if the cutting depth is to be 4 mm. The feed is 25 mm/min. Over run is 1/2 the cutter diameter.arrow_forward

- thickness is HW3.A block of steel has a length L-600mm and a width W-450mm. The Machined 10mm, once by Peripheral Milling and once by planing Machine.Calculate :Machining time for each operation if you know the following For peripheral milling: cutting speed V =80 m/min, Feed f-0.15mm/rev, the cutter .1 diameter D =50 mm with five teeth and depth of cut d =3mm For planing: clearance on both sides c =25mm, cutting speed V =36.56 m/min, retum to .2 cutting ratio m =0.25, feed f=5 mm/stroke and depth of cut d =5 mm .Calculate Material removal rate in both processes .3 Solutionarrow_forwardAn aluminum hollow shaft 200 mm outside diameter, 100 mm inside diameter and 500mm length from lathe chuck is to be face turned at the end. Its end face is finished at arotational speed of 400 rpm using a feed rate of 0.25 mm/rev. The side cutting edge angleor lead angle of the tool is 300. How much cutting time and maximum power is needed tofinish the facing operation with a 4 mm depth of cut. What is likely to be aperpendicularity error in this operation? Specific cutting energy = 0.025 W/ mm3/min andE = 50 kN/mm2.arrow_forwardFor the operation of straight turning in a lathe machine, the diameter of the workpiece is 80 mm, the length is 0.12 m, the cutting speed is 80 m / min, the feed is 0.5 mm / rev and the depth of cut is 0.002 m . Find the material removing rate and the time of machining.arrow_forward

- Turning Operation In a production turning operation, the foreman has decreed that a single pass must be completed on the cylindrical workpiece in 4.8 min. The piece is 400 mm long and 150 mm in diameter. Using a feed = 0.43 mm/rev and a depth of cut = 4.0 mm, what cutting speed must be used to meet this machining time requirement? Hint: Re-arrange the Tm equation to find v in m/min Tm= T.DO.L v.f 1.522arrow_forwardMachining time required reduce a mild steel rod of diameter 60mm, initial length (L) 125mm to final length (L1) 120mm to 58 mm by turning a carbide insert. If the approach length and over run length are 5 mm and 1 mm respectively, take Cutting speed as 20 m/min and feed is =0.2 mm/rev, and the depth of cut is 0.5mmarrow_forwardIn turning of stales steel alloy, 1100 mm length and 400 mm diameter, the Feed was 0.35 mm/rev, and depth of cut = 2.5 mm. The tool used in this cutting is cemented carbide tool where Taylor tool life parameters are n = 0.24 and C = 450 (tool life (min) and cutting speed (m/min). Compute the cutting speed that will allow the tool life to be 10% longer than the machining time for this part.arrow_forward

- Quiz A piece of Low carbon steel has (85mm) length machined by a lathe with cutting tool made of HSS, depth of cut (2mm), feed (0.2mm/rev) and (4) number of cycles with (30m/min) cutting speed. If the final diameter is (44mm). calculate the machining time of this piece.arrow_forwardA cylinder of 155 mm diameter is to be reduced to 150 mm diameter in one turning cut with a feed of 0.15 mm/rev and a cutting speed of 150 m/min on a NC lathe. What are the programmed feed rate and the material removal ratearrow_forwardThe workpiece of size 50 mm x 90 mm length is to be reduced to 0 42 mm x 85 mm. If the depth of cut is 0.5 mm, feed is 0.25 mm/rev and cutting speed is 45 m/min find the time taken to complete one job and production rate at the end of 8 hr shift.arrow_forward

Precision Machining Technology (MindTap Course Li...Mechanical EngineeringISBN:9781285444543Author:Peter J. Hoffman, Eric S. Hopewell, Brian JanesPublisher:Cengage Learning

Precision Machining Technology (MindTap Course Li...Mechanical EngineeringISBN:9781285444543Author:Peter J. Hoffman, Eric S. Hopewell, Brian JanesPublisher:Cengage Learning